For electrical contractors and other professionals working to construct and maintain complex commercial facilities, precision in every aspect of the job is critical. This is especially true in industrial engraving when components like panels, tags, and signs are critical to passing inspection. Having a clear and detailed plan is essential to ensure that the final product is accurate, meets project standards, and passes inspections without hiccups.

Industrial engraving labels electrical systems and equipment. The process requires skill and meticulous planning. Imprecise planning can lead to rework and delays—costly consequences in any contracting job.

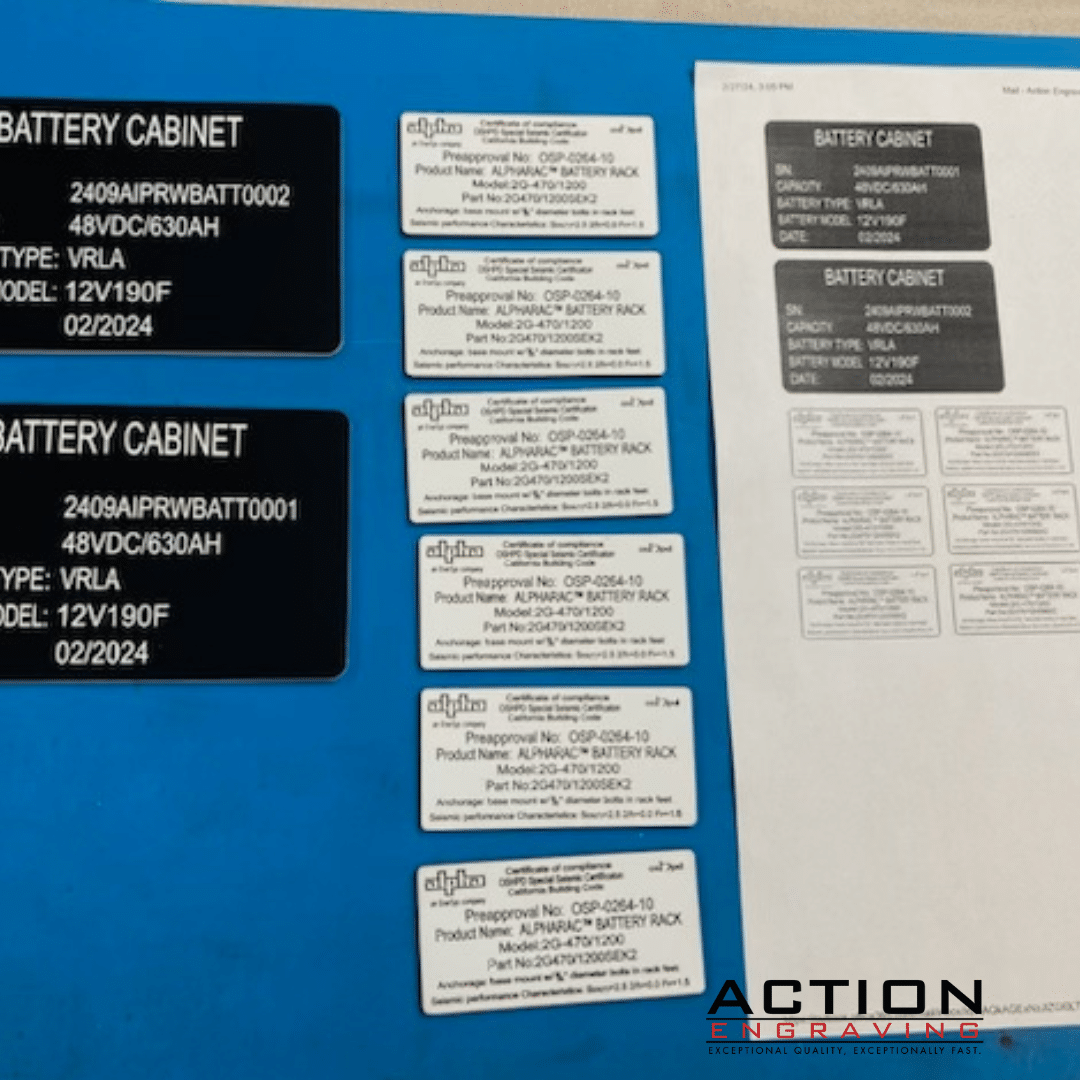

Clear, detailed plans are crucial from the start but they don’t delay the work we do. Our process helps prevent misunderstandings and ensures that expectations are met. Visuals play a crucial role in this process. Digital mock-ups are visual aids we use to ensure clear communication with our customers, and they serve as a reference point throughout our engraving process. Regular checks against the original visuals help catch any deviations early, maintaining quality and adherence to requirements.

The final products we create meet the aesthetic and functional requirements and pass internal inspections before delivery. Our focus on detail and compliance is critical in avoiding delays and additional costs associated with re-inspections or corrections at the job site. With our thorough planning and leveraging of visual communication, our customers trust us to deliver engraved tags, signs, and panels that meet the standards of the project and pass inspections smoothly.