When it comes to industrial materials, brass often plays a critical yet unsung role. Particularly, in the world of plumbing, heating, ventilation, and air conditioning (HVAC), brass shines brightly. Among its applications, its use as a material for engraved valve tags carries great importance.

What Are Engraved Valve Tags?

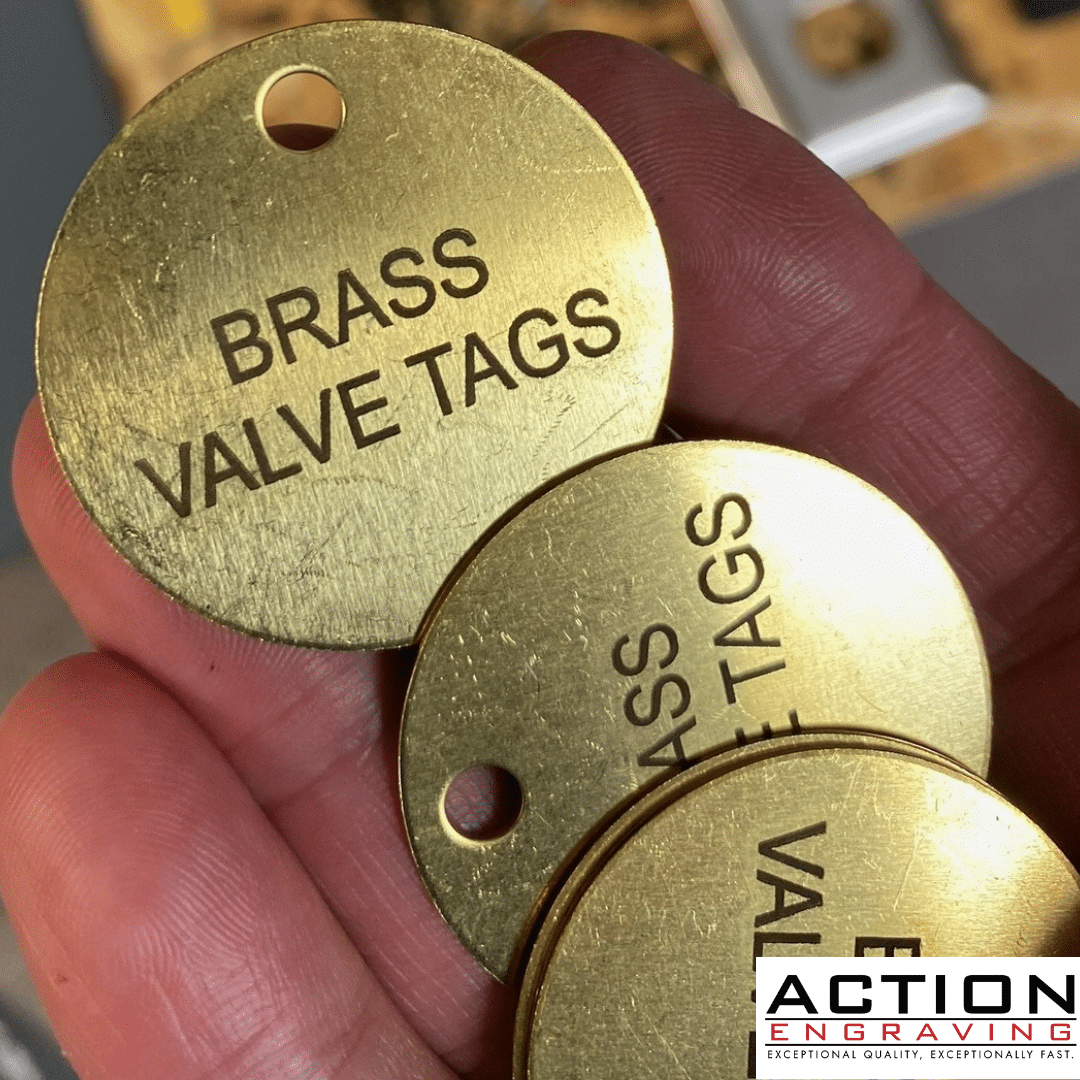

These small tags, often not more than a few inches in diameter, carry crucial information about the valves they’re attached to. They may include data on the valve’s function, operation, maintenance information, or even danger warnings. In essence, valve tags help in maintenance, identification, and safety procedures in complex piping systems.

Why Brass?

Brass is an alloy made primarily of copper and zinc. Its properties make it an ideal material for engraved valve tags for several reasons:

- Durability: Brass is known for its exceptional durability. It resists corrosion and wear, making it perfect for engraved valve tags, which often exist in harsh environments.

- Malleability: Brass is easily shaped and formed, allowing for easy manufacturing of tags of different shapes and sizes, and detailed engravings.

- Visibility: Its golden color stands out against the often grey or silver backdrop of industrial environments, making engraved brass tags easy to spot.

- Resistance to Heat: Brass has a high melting point, making it suitable for use in environments with fluctuating temperatures.

Brass Valve Tags in Action

In a large industrial complex with an extensive network of pipes and valves. Maintenance workers need to identify specific valves quickly for routine checks or in case of an emergency. This is where brass valve tags come in.

Due to their durable nature, these tags can withstand the rigors of an industrial environment while maintaining their legibility. In an emergency, the time saved by a clearly identifiable valve could be invaluable. Brass valve tags are resistant to many chemicals that are often present in these environments, ensuring they last longer than their plastic or aluminum counterparts.

The Manufacturing Process

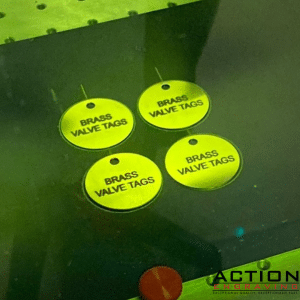

The manufacturing process of brass valve tags starts with sheets of brass. These sheets are stamped into the desired shapes and sizes. The malleability of brass allows for a variety of shapes and sizes to be made according to the specific needs of a project. Once the valve tags are formed, they are engraved with the necessary information. After brass valve tags are engraved, the tags are polished and coated, if necessary, to further enhance their durability and readability.

Who to trust to make your Engraved Valve Tags

When it comes to selecting a company for your engraved brass valve tags, you need a partner that understands the importance of quality, precision, and reliability. That’s where Action Engraving stands out. Here’s why you should trust us with your brass valve tag needs:

Expertise and Experience

With several years in the industry, Action Engraving has amassed a wealth of knowledge and expertise in the engraving business. We understand the intricacies involved in the manufacture of brass valve tags and are well-versed in industry standards and best practices.

Quality Materials and Craftsmanship

At Action Engraving, we use high-quality brass to ensure your tags can withstand harsh industrial environments. Our team of skilled artisans pays keen attention to detail, ensuring each engraving is clear, precise, and easy to read. The final product is not only functional but also aesthetically pleasing.

Custom Solutions

We know that every project is unique. Whether you need a specific shape, size, or detailed information on your valve tags, we can provide a custom solution to meet your needs. Our team works closely with you to understand your requirements and deliver a product that meets and exceeds your expectations.

Timely Delivery

We understand the importance of timelines in your operations. That’s why we’re committed to meeting your deadlines without compromising on quality. Our efficient processes and dedicated team ensure that your valve tags are ready when you need them.

Excellent Customer Service

At Action Engraving, we believe in building long-term relationships with our clients, and we are always ready to assist you. Your satisfaction is our priority.

In conclusion, brass valve tags may be small components, but their importance in maintaining order and safety in industrial settings is immeasurable. At Action Engraving, we understand this and are committed to providing the highest quality, precision, and service in creating your brass valve tags. When you choose us, you’re choosing a partner who values your business as much as you do.

Above: Brass Valve Tags during the engraving process